INSTALLATION GUIDE

INSTALLATION GUIDE FOR SOLAR WATER HEATING SYSTEM

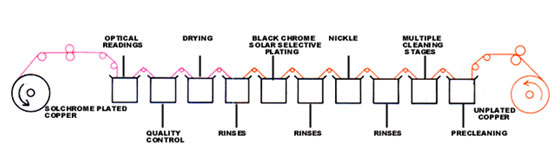

Manufacturing Process

Our manufacturing process is based on years of research and machine development. Our production line is designed for fully automatic operation.

- Each roll of copper goes through precleaning and rinsing stages before nickel is applied.

- Subsequent to the nickel application the copper is rinsed again before the black chrome solar selective coating is applied and thereafter the surface is subjected to a series of chemical rinses after which it undergoes an extensive drying period.

- The quality department then performs a series of tests to ensure that our customers receive an excellent product.

- During production optical readings are taken every 30m to check Absorptivity (α) and Emissivity (ε) levels.These readings must fall within our rigid specifications of 0.96 ± 0.02 (α ) and 0.12 ± 0.02 (ε) .

- The continuous manufacturing process is the key to the consistently high optical readings achieved.

- The coating thickness is controlled by line speed, tank temperature and current density.

- This process ensures production of a much higher quality solar selective surface than traditional batch electroplating.

The Nickel Undercoat ensures

- Better Moisture resistance,

- Better adhesion of coatings on the base metal,

- Better control of emissivity and

- A long life for the coatings.